What Is the Difference Between a Camshaft and a Crankshaft?

- Autolast Ghana

- Dec 22, 2022

- 4 min read

Updated: May 2, 2024

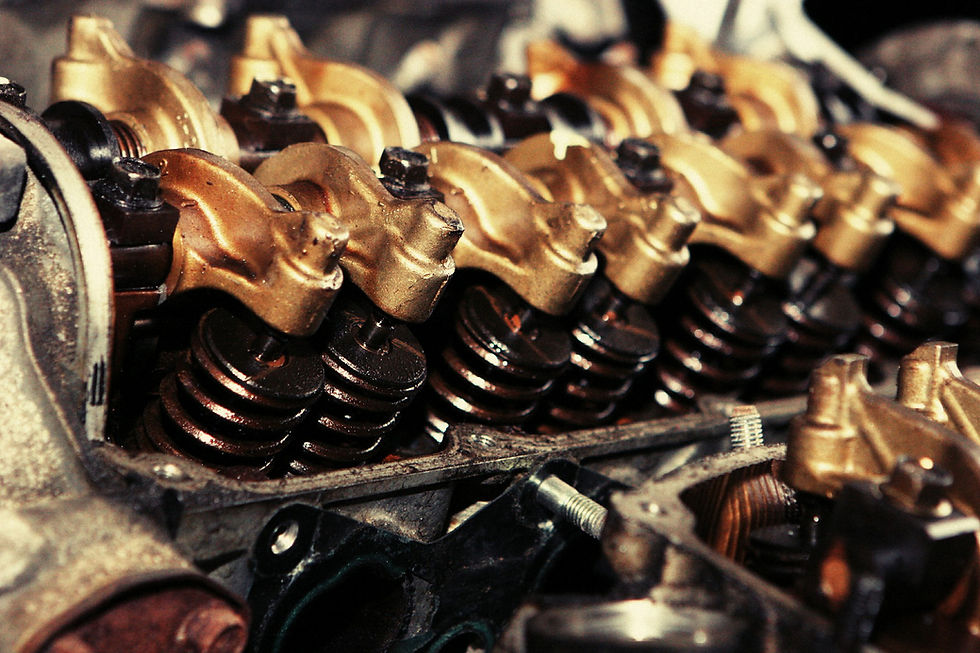

CAMSHAFT

To put it simply, the camshaft is a metal item in the shape of a rod. It has cam lobes that are oval-shaped (or, in rare cases, pointy). Its function is to open and close the valves on every cylinder of the engine.

The camshaft rotates while the engine runs, contacting the rocker arms with its lobes to open the engine valves. In accordance with the engine cycle, the valves open and close, permitting the air/fuel combination to enter the cylinder and the exhaust gases to exit. The valves are spring-loaded, so when the spring decompresses after the lobe has opened the valve, it also closes the valve. The timing belt, also known as a cambelt, controls the timing of the camshaft and is timed to the engine's motion. The valve opens in sync with the engine cycle, protecting against mistiming-related damage to the valve or cylinder.

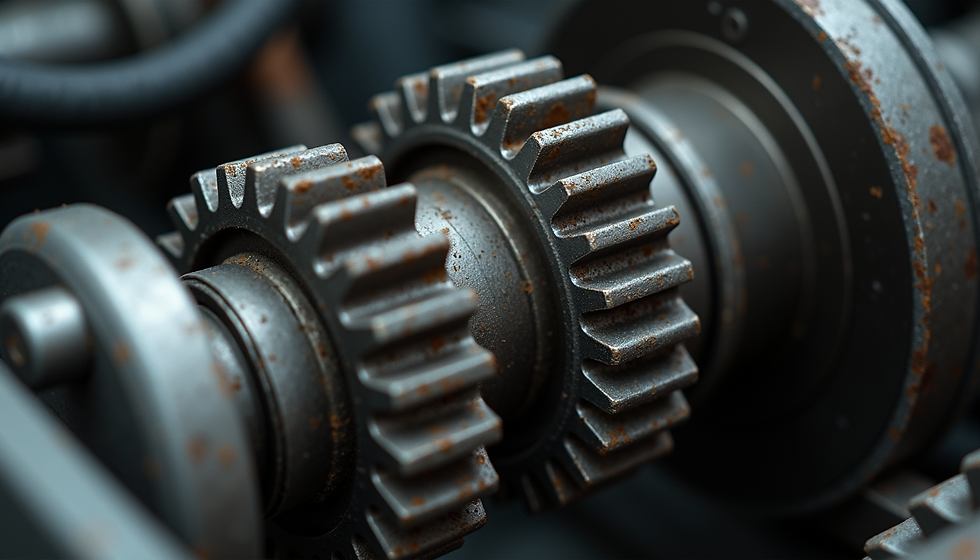

CRANKSHAFT

The crankshaft is, very literally, a shaft that is propelled by a crank mechanism. It travels down the motor's bottom and transforms the pistons' vertical movement into horizontal rotation. This allows it to harness the power generated by the burning of the fuel and air.

Multiple cylinders turn a single crankshaft-shaped drive shaft in car and watercraft engines. There is always at least one cylinder supplying power and moving the car forward since each one fires at a little different time. Rods that connect to the piston rods inside the cylinders secure the cylinders to the crankshaft.

Generally speaking, cams perform the opposite function of cranks by converting rotating motion into reciprocating motion. On top of an oval wheel that is occasionally positioned off-center lays anything you need to raise and lower (or move back and forth) (the cam). The thing that the cam supports moves up and down as it revolves.

Both methods completely do away with the pushrods and place the rocker arms up against the camshaft. This has a few benefits of its own and enables the sparkplug to be positioned in the center of the combustion chamber for greater efficiency.

By creating an electrical signal depending on the location of the trigger wheel (variable reluctance sensor) or metal rotor, camshaft and crankshaft sensors keep track of the positions of the engine's crankshaft and camshaft (Hall effect sensor).

The engine control computer and/or ignition control module utilize this data to sequence the timing of the fuel injectors and ignition.

What location do these sensors have?

The Camshaft Position sensor includes a cylindrical part that fits into the cylinder head of the engine, where it is generally positioned.

In an engine, camshafts are often placed above the cylinders and are typically composed of steel or cast iron. The two types of camshafts that are frequently utilized are SOHC (Single Over-Head Cam) and DOHC (Dual Over-Head Cam).

The timing cover or the side of the block with a cylindrical section that fits into the block are the typical locations for the crankshaft position sensor.

What kinds of camshaft and crankshaft sensors are there?

The most typical use for hall effect sensors is in the automobile industry, where they are used to measure the speed of rotating objects like wheels, crankshafts, and camshafts.

Hall effect sensors are preferred because of their precision across a wide speed range and resilience to corrosion, water, dirt, and muck. These are made of a permanent magnet that is stationary and a semiconductor that houses an analog to digital (A/D) signal converter.

The electronic controls of the car use the square wave electrical signal generated by the A/D inverter to identify the position of the engine's camshaft or crankshaft.

A permanent magnet and a pole piece make up a variable reluctance sensor, an analog signal-generating device.

A signal is produced as the metal cog of the tone ring or reductor wheel approaches the sensor tip, and it decreases as the gear goes away. With speed and closeness of the sensor to the tone ring, the signal strength grows.

A magneto resistive sensor is a machine that converts mechanical motion into an electrical signal using a magnetic field. It needs a power source to function. Due to its higher precision and resistance to electromagnetic interference, this type of sensor is used in CMP, CKP, ABS, and steering wheel speed sensors (EMI).

Possible signs of a damaged crankshaft or camshaft sensor P0335 to P0349 Codes Scanner Scan Tool: Cranking Had No RPM Present System of Ignition - Engine Misfire System Ignition - Poor Idle Quality System for Ignition - Hard Starting Fuel System: Poor Power Fuel System: Stalling Fuel System: No Fuel Injector Pulse Fuel System: Poor Fuel EconomyIgnition System: No Spark Fuel System: No Fuel Injector Pulse TIP - Very exact synchronization between the crankshaft position sensor (CKP) and the camshaft position sensor (CMP) is required for Chrysler engines.

A range of engine performance issues are caused by an improper synchronization. The best approach to verify that the sensors are aligned is with a dual trace lab scop because the CMP and CKP Synch data PIDs might be deceiving.

#Camshaft #Crankshaft #EngineParts #AutomotiveEngineering #MotorMechanics #InternalCombustion #VehicleMaintenance #MechanicalComponents #PowerTransmission #AutoRepairShop

Comments