Understanding Cylinder Scuffing and Wear: Causes, Effects, and Prevention Strategies

- Autolast Ghana

- Aug 24, 2025

- 5 min read

Cylinder scuffing and wear pose serious challenges in engine maintenance, especially for marine diesel engines. These conditions can lead to decreased efficiency and costly repairs if not addressed effectively. In this article, we will explore the causes of cylinder scuffing and wear, their effects on engine performance, and actionable strategies for prevention.

What Causes Cylinder Scuffing and Wear?

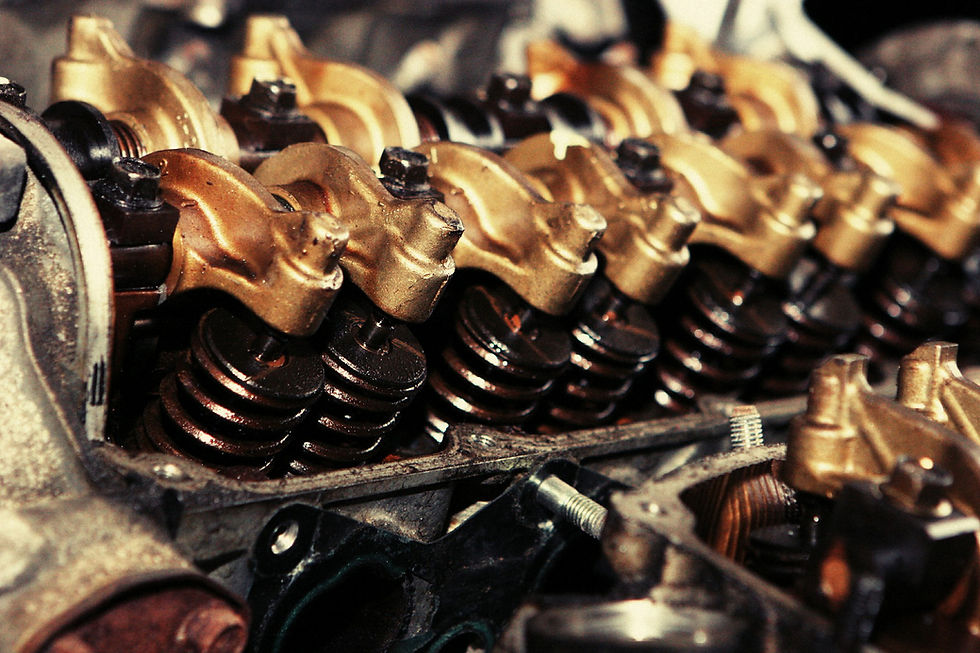

Cylinder scuffing involves the abrasive action occurring when the piston skirt rubs against the cylinder liner, leading to wear. This friction can significantly hinder engine efficiency and potentially result in catastrophic failures if not managed properly.

One primary cause of cylinder scuffing is inadequate lubrication. Proper oil levels are critical to creating a protective film between moving parts. When oil is low, contaminated, or has broken down, metal surfaces can come into direct contact, leading to scuffing. For instance, an engine running with insufficient oil can experience increased friction, ultimately wearing down components 50% faster than normal.

Another contributing factor is the presence of foreign particles like dust, dirt, and metal shavings. These contaminants can enter the cylinder through the air intake or fuel. According to industry studies, even small particles—measuring less than 10 microns—can act as abrasives, worsening scuffing and accelerating engine wear.

Temperature fluctuations also impact cylinder scuffing. High operating temperatures can cause the piston and cylinder liner to expand, creating tighter tolerances. This can increase friction between components by as much as 30%, further exacerbating scuffing.

By maintaining proper oil levels, keeping engines clean, and managing temperature effectively, you can significantly reduce the risk of cylinder scuffing and prolong engine life.

What is the Cause of Scuffing?

In addition to lubrication and contaminants, several other factors contribute to scuffing in engine components. For instance, improper assembly or misalignment of parts can cause uneven wear and increase the likelihood of scuffing. Engines assembled with precision can perform at optimal levels, while misaligned components may experience wear rates up to 20% higher.

An inadequate cooling system can also result in overheating, which can lead to oil breakdown and excessive wear on the engine. Regular inspection and maintenance of cooling systems can prevent these issues, ensuring that temperatures remain within the ideal range.

Aging equipment is another significant factor. As engines age, materials deteriorate, making them more vulnerable to scuffing. According to reports, replacing worn components in an aging engine can reduce scuffing by up to 40%, highlighting the importance of timely parts replacement.

What Causes Cylinders to Wear?

Cylinder wear primarily results from long-term friction, but many variables can affect the severity and rate of this wear. One of the key contributors is the condition of the lubricating oil. Oil that is rich in viscosity and enhanced with proper additives performs better in reducing friction. When oil degrades, its viscosity drops, leading to increased wear rates as high as 50%.

Operational stresses also play a role. Engines subjected to high RPMs or heavy loads generate greater friction, resulting in accelerated wear. Additionally, corrosive substances in the combustion chamber can worsen wear significantly. For example, data shows that engines running on low-quality fuels are 30% more likely to experience wear due to residue accumulation.

Understanding the type of fuel being used is crucial. High-quality fuels with cleaner burn characteristics lead to less engine wear, emphasizing the importance of fuel choice in maintenance strategies.

What is Scuffing in an Engine?

Scuffing refers specifically to the abrasive contact between the piston and cylinder liner. While lubrication should maintain separation between these parts, failure in oil delivery leads to friction and subsequent scuffing. Scuffing can be identified by visible scratches or grooves along the cylinder wall. If untreated, this can cause issues such as reduced compression, increased oil consumption, and even engine failure.

Regular inspections of the engine can help in identifying early signs of scuffing, allowing for timely maintenance to prevent severe damage.

Cylinder Wear

Cylinder wear is the gradual thinning and deterioration of the cylinder wall. Over time, this can lead to a drop in engine performance due to loss of compression. The two primary forms of wear are abrasive and adhesive. Abrasive wear occurs due to hard particles damaging the wall, while adhesive wear happens when metal surfaces bond together under high stress.

Factors like poor lubrication and mechanical issues can intensify wear. Regular measurements and monitoring can help track wear rates, allowing operators to implement proactive maintenance strategies.

Liner Scuffing

Liner scuffing is a close relative to cylinder scuffing, typically occurring in tandem. Cylinder liners are specifically designed to provide a durable surface for piston movement. However, insufficient lubrication or contaminants can result in scuffing on the liner surface.

Consequences of liner scuffing include increased oil consumption, exhaust smoke, and power loss. Severe cases may even require expensive repairs, including replacing the entire cylinder liner, which can cost thousands of dollars.

To combat liner scuffing, ensure a clean engine environment, monitor oil quality, and enforce proper lubrication practices.

Cylinder Liner Polishing

Cylinder liner polishing is a maintenance technique aimed at rejuvenating worn liners and enhancing surface quality. Polishing can eliminate minor imperfections, creating a smoother surface for piston rings. This process may involve abrasive tools or chemical treatments.

The benefits of this technique include improved oil retention and performance due to reduced friction. Regularly scheduled polishing, particularly in high-performance applications, can prevent premature wear and extend the life of engine components.

Cylinder Liner of Marine Diesel Engine

In marine diesel engines, cylinder liners are vital for overall performance, as they operate in demanding conditions, facing higher pressures and corrosive environments compared to land-based engines. Special materials and designs aim to ensure durability against wear, but they are still not immune to issues like scuffing.

Following strict maintenance protocols is essential. This includes regular inspections for wear, ensuring quality fuel selection, and careful monitoring of oil conditions, all of which play a significant role in sustaining engine health.

Cylinder Liner Wear

Cylinder liner wear is a normal outcome of engine operation but can be effectively managed. Understanding wear mechanisms—such as abrasion and corrosion—allows operators to develop targeted maintenance strategies. For instance, excessive wear in specific areas can indicate alignment issues, while uniform wear might suggest lubrication problems.

Regular inspections enable early detection of wear patterns. Implementing corrective measures, such as adjusting operating conditions or replacing damaged components, can help prevent costly failures.

Final Thoughts

and wear are significant issues affecting engine performance and longevity, particularly in maritime environments. By understanding their causes—including lubrication failures, contaminants, and operational stresses—operators can implement effective prevention strategies.

Focusing on proper lubrication practices, proactive maintenance, and timely interventions, such as polishing and addressing wear patterns, can profoundly enhance engine reliability. By prioritizing these strategies, you not only improve operational efficiency but also reduce costs associated with repairs and replacements.

Staying proactive and informed on these matters ensures healthier engines and extends their operational lifetimes significantly.

Comments