Car alternators

- Autolast Ghana

- Dec 20, 2021

- 3 min read

Updated: Jan 6, 2023

An alternator is characterized as a machine that changes mechanical energy over to electrical energy through exchanging flow

(at a particular voltage and recurrence).

Alternators are otherwise called simultaneous generators.

Your vehicle's electrical framework comprises three principal parts: the battery, a voltage controller, and an alternator.

The alternator gets its name from the expression "rotating flow," as it changes mechanical energy over to electrical energy. Along with the battery, the alternator produces the ability to run your vehicle's adornments, including the lights, sound and route frameworks, and the warmer. There are various kinds of alternators and applications where they are utilized, other than in your vehicle.

Where is an Alternator Used For?

Alternators produce the power for the electrical frameworks of present-day vehicles. Beforehand, DC generators or dynamos were utilized all things being equal. Yet, later the advancement of the alternator, they supplanted DC dynamos since alternators are more powerful and lightweight.

Since the electrical arrangement of engine vehicles requires direct flow and not exchanging flow, an alternator is utilized close by a diode rectifier to change the flow from AC over to DC.

Notwithstanding this need to change the current from AC over to DC, an alternator is as yet utilized as it does not have the convoluted replacement present in a DC generator.

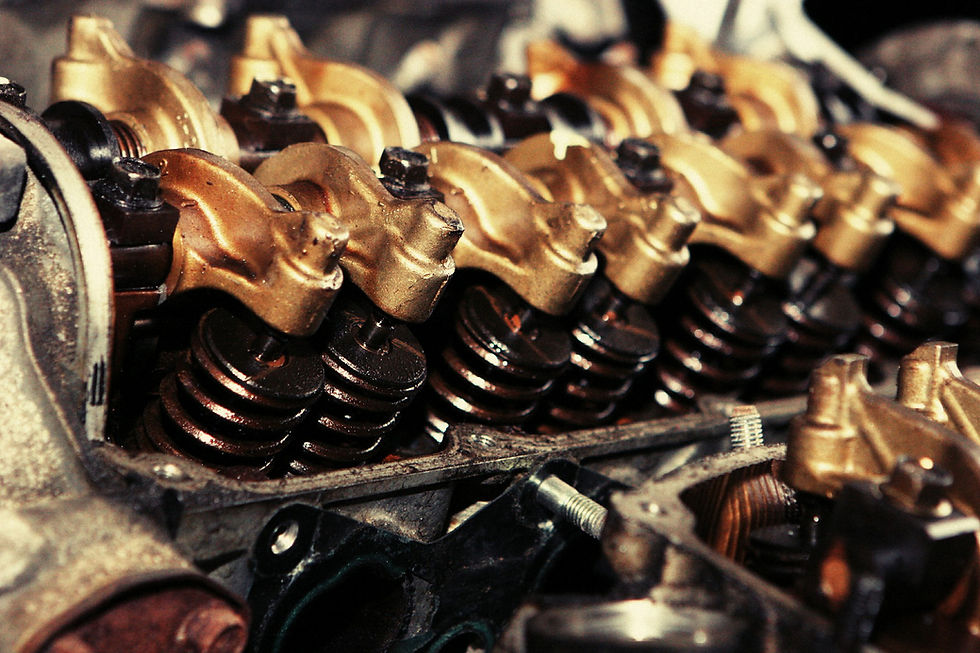

This specific sort of generator utilized in the vehicle is known as an auto alternator (figure out how an alternator is developed).

One more utilization of alternators is in the diesel-electric trains. The driving force of this train is only an alternator, driven by a diesel motor.

The substituting current delivered by this generator is changed over to DC by incorporated silicon diode rectifiers to take care of all the DC foothold engines. These DC footing engines drive the wheel of the train.

We additionally utilize this machine in marine like a diesel-electric train. We uniquely plan the simultaneous generator utilized in marine and naval forces with suitable variations to the salt-water climate.

The normal result level of a marine alternator is around 12 or 24 volts. In huge marine sheep, more than one unit is utilized to give monstrous power.

In this marine framework, the energy created by the alternator is first amended then utilized for charging the motor starter battery and helper supply battery of the marine.

One of the essential employments of alternators is in the development of mass ac power for business purposes. In nuclear energy stations, in hydel power plants, even in thermal energy stations, alternators just proselyte mechanical energy to electrical energy for providing to the power framework.

Sorts of Alternators

Alternators or simultaneous generators can be arranged in numerous ways relying on their applications and plans.

The five distinct sorts of alternators include:

Car alternators – utilized in current cars.

Diesel-electric train alternators – utilized in diesel-electric various units.

Marine alternators – utilized in marine applications.

Brushless alternators – utilized in electrical power age plants as the primary wellspring of force.

Radio alternators – utilized for low band radio recurrence transmission.

We can order these AC generators (alternators) in numerous ways, yet the two principle classes relying upon their plan are:

Notable Pole Type

Smooth Cylindrical Type

Notable Pole Type

We use it as a low and medium-speed alternator. It has countless projecting shafts having their centers catapulted or dovetailed onto a substantial attractive wheel of cast iron or steel of good attractive quality.

Such generators get portrayed by their huge breadths and short pivotal lengths. These generators resemble a major wheel. These are mostly utilized for low-speed turbines, for example, in hydel power plants.

Smooth Cylindrical Type

We use it for a steam turbine-driven alternator. The rotor of this generator pivots at an exceptionally rapid. The rotor comprises a smooth strong manufactured steel chamber having specific quantities of openings processed out at stretches along the external fringe for obliging field loops.

These rotors are planned generally for 2 posts or 4 shafts super generator running at 36000 rpm or 1800 rpm separately.

Comments